While recently walking through the buzzing halls of BEYOND Expo in Macau, I literally stopped in my tracks when I spotted what looked like alien artifacts masquerading as footwear. These weren’t your average kicks—they were sculptural, otherworldly creations that seemed to defy conventional manufacturing logic. Welcome to the universe of SCRY Lab, a Beijing-based brand that’s flipping the script on how we produce, consume, and think about fashion. Their tagline says it all: “We are not predicting the future, we are creating the future.”

While they’ve been around for a few years now, SCRY Lab is still going strong, so we wanted to tap into what they’ve been up to. But first, a little back story. SCRY Lab emerged from the collaborative vision of co-founders Olivia Cheng and Zixiong Wei, whose backgrounds span innovation design and engineering. Their paths crossed at a time when both were questioning traditional manufacturing constraints. Wei, with his interest in computational design and digital fabrication, had been experimenting with 3D printing technologies, while Cheng was exploring how digital processes could revolutionize fashion’s notoriously wasteful production methods.

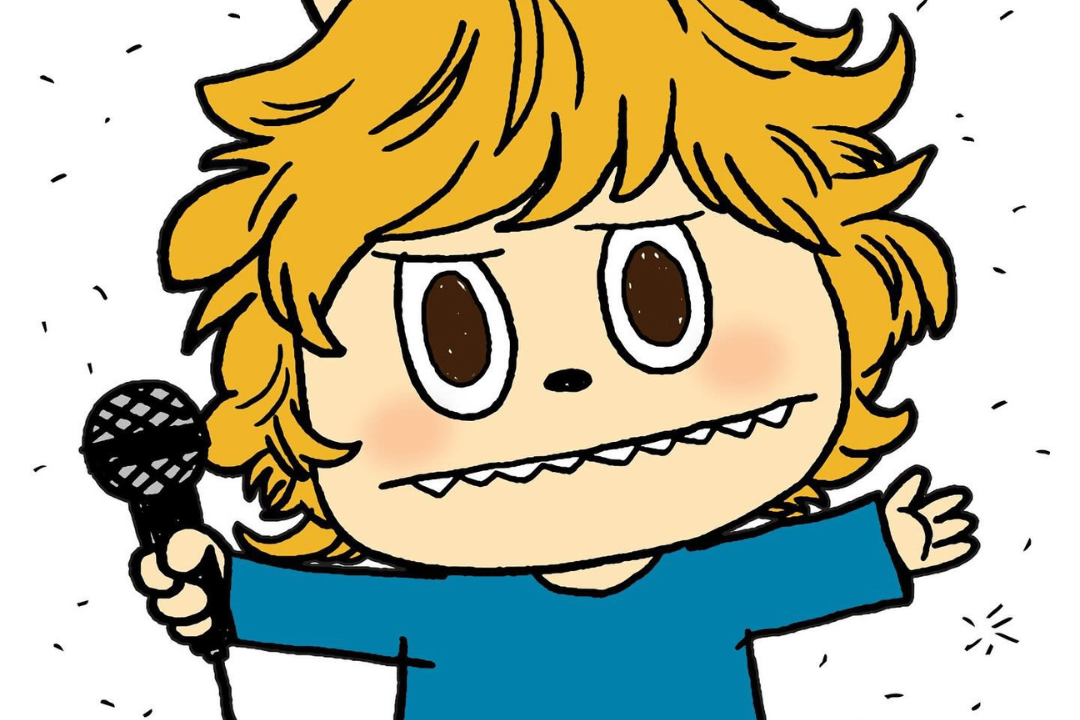

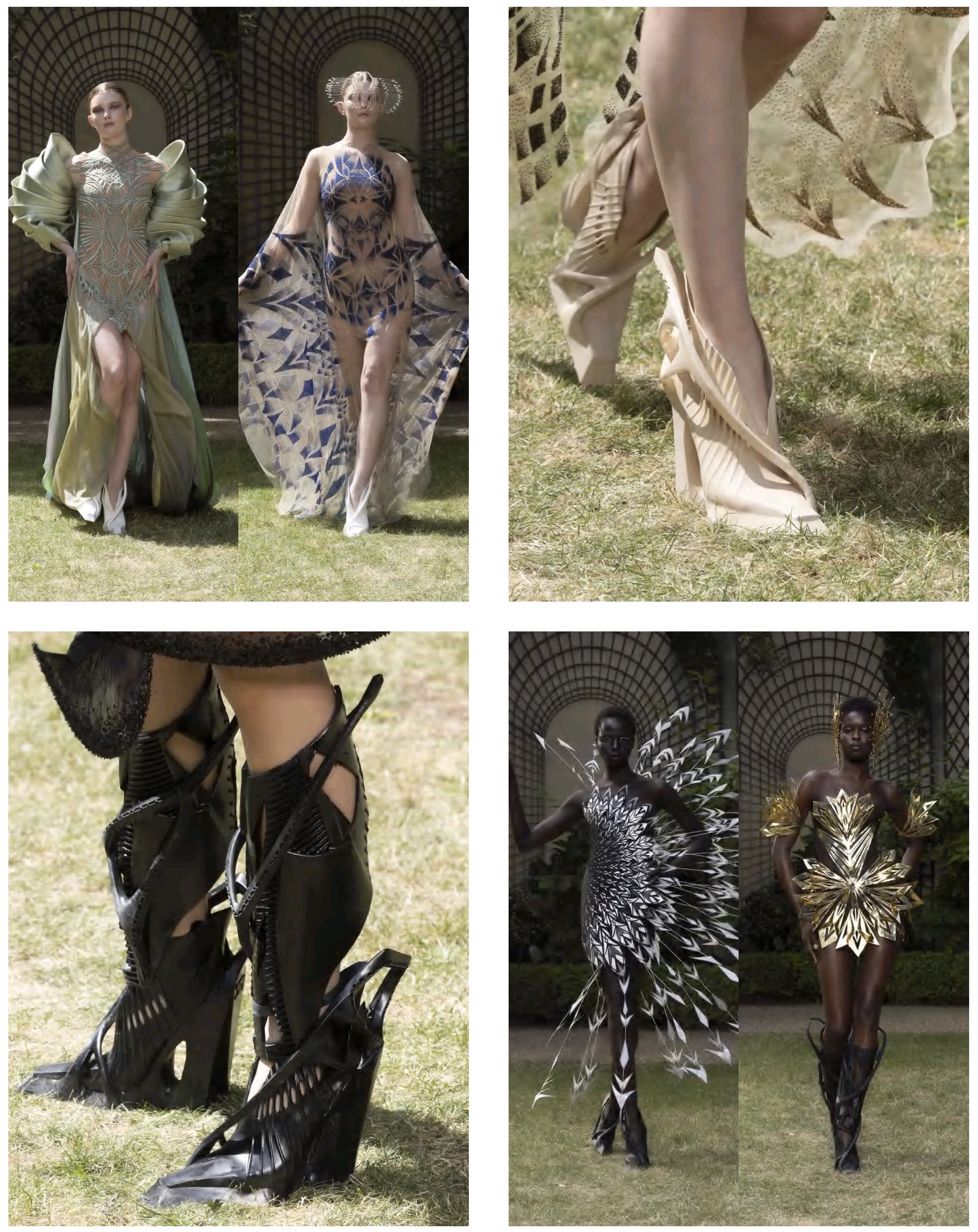

What sets SCRY Lab apart is its “digital embryo” approach to design. Unlike traditional fashion houses that start with sketches and patterns, SCRY Lab begins in the digital realm, using parametric design software to create complex structures that often mimic organic forms found in nature. The result? Otherworldly creations that look like they’ve been teleported from a sci-fi (or perhaps no-longer-fictional?) future. We’re talking sculptural shoes with impossible geometries, handbags with intricate lattice structures, and jewelry that resembles alien artifacts.

The most mind-blowing aspect? Their shoes are each printed as a single piece, with varying densities and flexibilities built into different zones of the same continuous structure. This eliminates the need for glues, stitching, and the assembly of multiple parts, dramatically reducing waste and labor while opening up entirely new design possibilities.

The manufacturing time is remarkably efficient compared to traditional methods. The SCRY ZERO C03 slippers I tried on at BEYOND Expo take just 90 minutes to print from start to finish. More complex designs like their SCRY Vortex boots require 90 to 120 minutes—still lightning-fast compared to conventional production timelines that can stretch for weeks when accounting for component manufacturing, shipping, and assembly.

Holding the SCRY ZERO C03 slippers at their booth, I was immediately struck by how light they felt. It was like holding structured air. The fully hollow, lattice-like design creates an optical illusion: they look solid but weigh next to nothing. Slipping them on was the real revelation. Despite their rigid, sculptural appearance, they flexed perfectly with each step. The sensation was unlike any footwear I’ve experienced, as if I were walking on a responsive cloud that somehow provides both cushioning and support. These slippers retail for 190 USD, making them SCRY Lab’s most accessible shoe design. While not cheap, the price feels reasonable considering each pair is essentially a piece of wearable tech art, produced on demand rather than mass-manufactured.

The SCRY Vortex boots that were displayed alongside (670 USD) showcased even more advanced capabilities, with sections that appear solid but incorporate programmed flexibility at precisely the points where your foot needs to bend. While not physically displayed at the booth, I was also impressed by images of the SCRY Predator Skull shoes (1,090 USD), with their feline-inspired fanged structure. Likewise, the hooved Predator Extra (1,435 USD) wouldn’t look out of place in a high-concept editorial shoot or on a cutting-edge runway.

The collection extends beyond shoes to include the tiny SCRY Thorn minibags (starting at 159 USD)—perfect for AirPods—and the larger SCRY Zero handbags (from 269 USD). Their jewelry line features stainless steel bracelets (from 170 USD) and rings (from 80 USD) with organic, otherworldly structures that look like they have been grown rather than manufactured.

These pieces demonstrate how 3D printing enables a new design language: organic, complex structures that would be impossible to create through molding or traditional manufacturing. The technology isn’t just making production more efficient; it’s expanding what’s aesthetically possible.

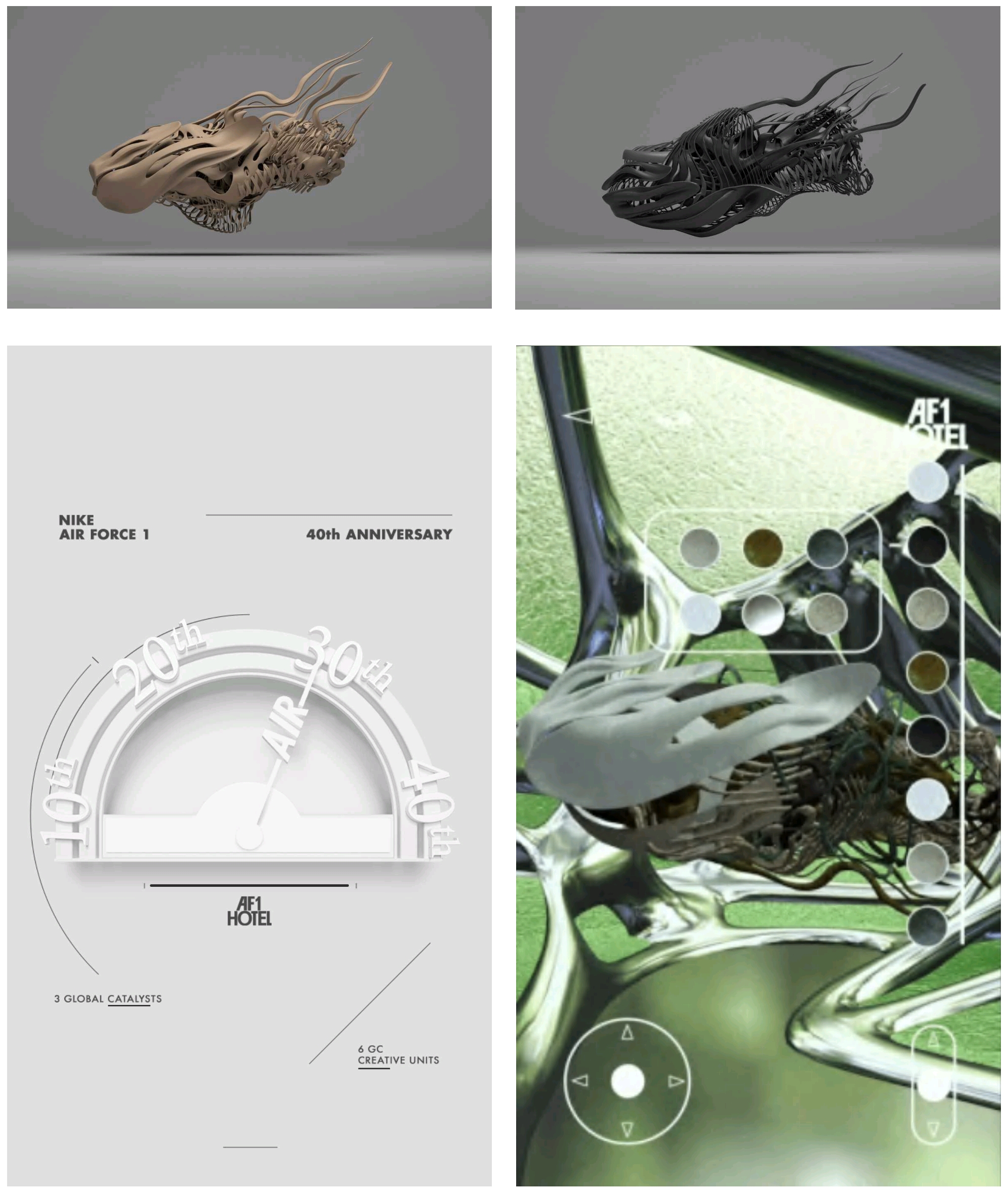

SCRY Lab’s innovations haven’t gone unnoticed by fashion’s establishment. They’ve collaborated with major brands including Nike, UGG, and Timberland, looking to explore the bleeding edge of manufacturing technology, bringing their computational expertise to traditional fashion houses eager to modernize their approach. These partnerships signal an important shift: 3D printing is moving from the fringes of fashion into the mainstream conversation. That said, SCRY Lab isn’t trying to replace traditional craftsmanship, but rather introduce new possibilities that complement existing techniques.

Perhaps the most promising aspect of SCRY’s 3D printing approach is its sustainability potential. Traditional footwear manufacturing is notoriously wasteful. Nike has acknowledged that materials account for about 70% of their carbon footprint, with much of that coming from manufacturing processes. Meanwhile, 3D printing is an additive process, using only the material needed rather than cutting away excess. It eliminates the need for multiple materials and adhesives, and it enables on-demand production (reducing overstock waste). While the polymers currently used aren’t perfect from a sustainability standpoint, the technology continues to evolve with more eco-friendly materials being developed.

As I reluctantly returned the SCRY ZERO slippers to the display at BEYOND Expo, I couldn’t help but wonder if I was experiencing a glimpse of fashion’s inevitable future. Will we one day look back at traditionally manufactured shoes the way we now view flip phones—as charming but primitive precursors to something far more advanced?

What SCRY Lab represents isn’t just a cool new product category; it’s a fundamental rethinking of how fashion items can be conceived and created. In a world where fashion often seems caught between fast-fashion disposability and luxury exclusivity, SCRY offers a third path—one where technology enables both creative expression and responsible production. Whether this vision becomes fashion’s mainstream future remains to be seen, but one thing is certain: SCRY Lab is already wearing tomorrow’s fashion today.

If you’ve missed my other story on why smart glasses from China are leap years ahead of of the game, check that out here.

Cover image via Culted.